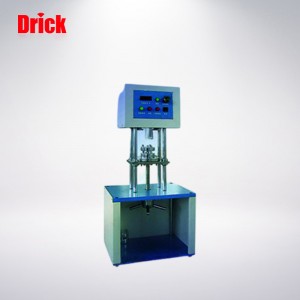

ZWS-0200 Compression Stress Relaxation Tester

It is especially suitable for the application research of rubber products as sealing materials. It conforms to GB1685 “Determination of Compression Stress Relaxation of Vulcanized Rubber at Normal Temperature and High Temperature”, GB/ T 13643 “Determination of compression stress relaxation of vulcanized rubber or thermoplastic rubber ring sample” and other standards. The compressive stress relaxation instrument has simple structure, convenient operation, digital display of compressive force value, intuitive and reliable, and has a wide range of applications.

Product Parameters:

1. Sensor force measurement/display range: 2500

2. Force measurement accuracy: 1% (0.5%)

3. Power supply: AC220V±10%, 50Hz

4. Dimensions: 300×174×600 (mm)

5. Weight: about 35kg

Operation Method:

1. Select the appropriate limiter according to the test requirements and fix it with 3 bolts.

2. Connect the two wires from the back panel of the digital display box to the indenter and the terminal screws on the fixture backing plate. Note: Generally, these two wires should not be connected to the rack, sensor, etc.

3. Turn on the power, turn on the power switch, the power indicator light is on, and it can be put into use after warming up for 5-10 minutes.

4. When it is necessary to reset, to discharge the power, press and hold the “clear” button.

5. Carefully clean the operating surface of the fixture, and select the limiter according to the type of sample. Use a dial indicator to measure the height of the center of the sample. Put the sample into the fixture so that the sample and the metal rod are on the same axis. The clamp is tightened with a nut to compress the sample to the specified compression rate.

6. After 30+2min, put the clamp into the relaxation instrument, pull the handle to raise the movable plate, and the indenter contacts the metal rod, but at this time the flat part of the metal rod is still in contact with the upper pressure plate of the clamp, and the two wires are in conduction. Status, the contact indicator light is off, the movable plate continues to rise, the sample is compressed, the plane part of the metal rod is separated from the upper pressing plate of the fixture, the two wires are disconnected, the contact indicator light is on, and the displayed force value is recorded at this time.

7. Move the handle to lower the movable plate, and press the “Zero” button to measure the other two samples in the same way (according to the standard.)

8. After the measurement is completed, place the compressed sample (with clamps) in a constant temperature incubator. If the compression stress relaxation performance of the sample in a liquid medium is measured, it must be carried out in a closed container.

9. After placing it in the incubator for a certain period of time, take out the fixture or container, cool it for 2 hours, and then put it into the relaxation meter, and measure the compression force of each sample after relaxation, the method is the same as 4.6. Calculate the stress relaxation factor and percentage.

10. After the test is over, turn off the power, unplug the power plug, and coat the test fixture, limiter and other parts with anti-rust oil for storage.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top