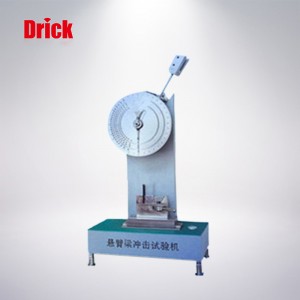

XC-22 Cantilever Beam Impact Testing Machine

The cantilever beam impact tester is used to determine the impact strength of non-metallic materials such as hard plastic, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic appliances, insulating materials, etc. It is divided into mechanical (pointer dial) and electronic. It has the characteristics of high accuracy, good stability, and large measuring range. The electronic type adopts circular grating angle measurement technology. In addition to the advantages of mechanical punching, it can also digitally measure and display the punching work, impact strength, pre-elevation angle, rise angle, The average value of a batch, the energy loss is automatically corrected. The cantilever beam impact testing machine series can be used for cantilever beam impact testing in scientific research institutions, colleges and universities, production inspection institutes at all levels, and material production plants. This series also has a micro-control type, which adopts computer control technology to automatically process the test data into a printed report. The data can be stored in the computer for query and printing at any time.

Product Description:

It is used to measure the impact strength of non-metallic materials such as hard plastic, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, insulating materials, etc. It is divided into mechanical type (pointer dial) and electronic type. It has the characteristics of high accuracy, good stability, and large measuring range. The electronic type adopts circular grating angle measurement technology. In addition to the advantages of mechanical punching, it can also digitally measure and display the punching work, impact strength, pre-elevation angle, rise angle, The average value of a batch, the energy loss is automatically corrected. The cantilever beam impact testing machine series can be used for cantilever beam impact testing in scientific research institutions, colleges and universities, production inspection institutes at all levels, and material production plants. This series also has a micro-control type, which adopts computer control technology to automatically process the test data into a printed report. The data can be stored in the computer for query and printing at any time.

Execution Standard:

The products meet the requirements of ENISO180, ASTMD256, GB/T1843 standards for test equipment.

Technical Parameters:

1. Energy range: 5.5J, 11J, 22J

2. Impact speed: 3.5m/s

3. Jaw distance: 22mm

4. Pre-yang angle: 160°

5. Dimensions: length 500mm×width 350mm×height 780mm

6. Weight: 110kg (including accessory box)

7. Power supply: AC220±10V 50HZ

8. Working environment: within the range of 10℃~35℃, relative humidity ≤80%, no vibration around, no corrosive medium.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top