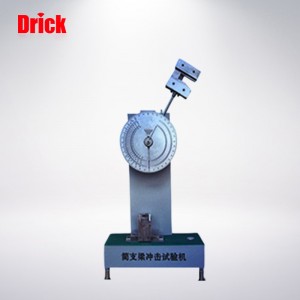

JB-300 Manual Impact Testing Machine

The JB-300 manual impact tester is used to measure the resistance of metal materials to impact under dynamic load, so as to judge the quality of the material under dynamic load. This testing machine is hand-controlled, and the pendulum, impact and braking are controlled manually. It is suitable for ferrous metals with large impact toughness, such as the impact performance test of steel and its alloy materials. GB229-2007 “Metal Material Charpy Pendulum Impact Test Method”. This series of impact testing machines is the first choice for physical and chemical laboratories in metallurgy, boiler pressure vessels, steel, steel pipes, hardware, casting, pumps, valves, fasteners, vehicles and ships, machinery manufacturing, petrochemicals, aerospace and scientific research institutions. Impact equipment.

product details

Product Description:

The JB-300 manual impact tester is used to measure the resistance of metal materials to impact under dynamic load, so as to judge the quality of the material under dynamic load. This testing machine is hand-controlled, and the pendulum, impact and braking are controlled manually. It is suitable for ferrous metals with high impact toughness, such as the impact performance test of steel and its alloy materials. GB229-2007 “Metal Material Charpy Pendulum Impact Test Method”. This series of impact testing machines is the first choice for physical and chemical laboratories in metallurgy, boiler pressure vessels, steel, steel pipes, hardware, casting, pumps, valves, fasteners, vehicles and ships, machinery manufacturing, petrochemicals, aerospace and scientific research institutions. Impact equipment.

Technical Parameter:

1. Maximum impact energy: 300 joules

3. Measuring range and division value: 0-300 Joules: 2 Joules/div 0-150 Joules: 1 Joules/div

4. Pendulum moment: (impact constant) M300=175.7356 joules M150=87.8678 joules

5. The distance from the center of the pendulum shaft to the center of the sample; 800 mm

6. Pre-yang angle of pendulum: 135 degrees, impact speed 5m/s

7. Specimen support span; 40 mm 70 mm

8.Included angle of impact knife: 30 degrees

9. Impact knife fillet radius: R2.0-2.5 mm

10. Dimensions: 1000*630*1520 (mm)

11.Weight: 320 kg

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top