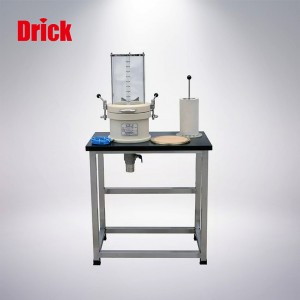

DRK504A Valli Beater (pulp crusher)

The DRK504A Valli beater (pulp shredder) is an international standard equipment for papermaking laboratories. It is an indispensable equipment for studying the pulping and papermaking process. The machine uses the mechanical force generated by the flying knife roll and the bed knife to convert various fiber slurries Carry out cutting, crushing, kneading, splitting, wetting and swelling and fiber thinning, and at the same time, the fiber produces cell wall displacement and deformation, and the rupture of the primary wall and the outer layer of the primary wall.

According to the pressure on the bedknife and the beating time, the changes of pulp with different beating degrees can be obtained. The Wali beating machine is widely used in the beating test of various plant fibers, synthetic fibers, carbon fibers, and glass fibers. It is a papermaking production test, Indispensable papermaking experimental equipment for quality control, process development, teaching and research experiments.

Technical Standard:

DRK504A Valley beater (pulp crusher) meets ISO 5264/I, TAPPI-T200 and GB7980-87 laboratory beating Valley (Valley) beater method (Pulps-laboratory beating-Valley beater method) and other standards.

Working Principle:

The metered and specified concentration of pulp is beaten between the flying knife and the bottom knife of the Valley beater. During the beating process, samples are taken at intervals and the freeness of the pulp is measured. This model can change the heavy thallium pressure, beating time, and automatically control the beating time to obtain different experimental results.

Product Parameters:

1. Volume: 23 liters

2. Slurry amount: 200g~700g absolutely dry pulp (tear into small pieces of 25mm×25mm)

3. Flying knife roller: diameter×length φ194MM×155MM

4. Rotation speed: (8.3±0.2) r/s; (500±10) r/min

5. Power supply: 750W/380V

6. Dimensions: 1240mm×650mm×1180mm

7. Packing size: 1405mm×790mm×1510mm

8. Water source status: gap or continuous water source is acceptable

9. Total weight: 230Kg

Note: Due to technological progress, the information will be changed without notice. The product is subject to the actual product in the future.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top