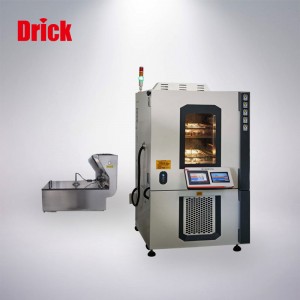

DRK258B Thermal Resistance and Moisture Resistance Test System

The DRK258B thermal and moisture resistance test system is used to test the thermal and moisture resistance of textiles, clothing, bedding, etc., including multi-layer fabric combinations.

Standards Compliant:

GBT11048, ISO11092 (E), ASTM F1868 and other standards.

DRK258B thermal resistance and moisture resistance test system features:

1. Test method: Method A evaporative hot plate method (made of special materials, replacing the previous porous plate form)

2. Highly simulated skin sweating effect.

3. Control operation: large-screen color touch screen, menu-style operation with Chinese and English interface.

4. The indoor bladder of the atmosphere is made of high-quality 316 stainless steel.

5. The atmospheric chamber adopts YM channel device to accurately control temperature and humidity,

6. Water level system: The sample plate water supply device is controlled by a special chip, and the water level error can reach 0.1mm.

7. The lifting and lowering range of the test bench is electric control: 0~70mm.

8. Equipped with a dedicated air duct, frequency conversion controls the wind speed on the upper surface of the test bench.

9. All devices that use water in the instrument are equipped with a water level indicator and a water level regulating valve, which have a water level protection function.

10. The environmental climate room has a built-in fluorescent lamp, which is also convenient for observing the sample.

11. High-quality casters imported from South Korea, easy to move, adjustable height, height adjustment range: 0~8mm.

12. Using microcomputer control and data processor, it can directly measure and calculate the various properties of the sample.

13. The experimental warehouse is wrapped with imported thermal insulation cotton to reduce environmental interference.

14. Equipped with imported temperature and humidity sensors to accurately measure the actual temperature and humidity data of the experimental chamber.

15. All water pipes in the instrument are made of engineering plastic pipes made in Taiwan, with a service life of ten years.

Technical Parameter:

1. Effective size of atmospheric chamber: 630mm×660mm×800mm (L×W×H);

2. The temperature range (precision) of the atmospheric chamber: 15℃~48℃±0.1℃; the range can be set freely and accurately controlled;

3. Humidity range of atmospheric chamber (precision): 30%RH~95%RH±2%RH; free setting within the range, precise control;

4. Atmospheric temperature and humidity conditions during thermal resistance test: 20℃±0.1℃ Resolution: 0.1℃ 65%±3% Resolution: 0.1% RH;

5. Atmospheric temperature and humidity conditions during humidity resistance test: 35℃±0.1℃ Resolution: 0.1℃ 40%±3% Resolution: 0.1% RH;

6. Wind speed control range and accuracy above the test board: 0~2m/s±0.05m/s;

7. The lifting range of the sample platform: 0~70mm±0.1mm, automatically lifting, so that the sample is subjected to precise and uniform wind blowing;

8. Thermal resistance range (resolution) and accuracy: 0~2m2·k/w (0.0001m2·k/w); ≤±2%;

9. Repeatability error of thermal resistance test: ≤±2%;

10. Moisture resistance range (resolution) and accuracy: 0~1000m2·Pa/w (0.01m2·Pa/w); ≤±2%;

11. Repeatability error of moisture resistance test: ≤±2%;

12. The temperature range and accuracy of the test board: 20~50℃±0.1℃;

13. Test board size: 254mm×254mm (L×W);

14. Sample measurement range: 0~70mm;

15. Overall size: 1000mm×750mm×1800mm (L×W×H);

16. Power supply: AC220V, 4KW;

17. Whole machine weight: 300kg;

Scope of supply:

1. 1 host

2. Sealing bead 1 pc

3. 1 set of standard sample cloth

4. 1 set of standard moisture-permeable membrane

5. 2 water pipes

6. 1 product certificate

7. Product instruction manual 1 copy

8. Invoice 1

9. 1 acceptance sheet

10. Product album 1 copy

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top