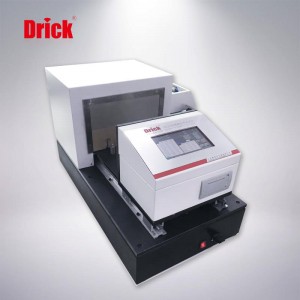

DRK201 Shore Hardness Tester\Shore Hardness Tester

DRK201 Shore Hardness Tester Rubber Hardness Tester is an instrument for measuring the hardness of vulcanized rubber and plastic products.

Features

The sampler has beautiful appearance, compact and reasonable structure, labor-saving operation and convenient use.

Applications

The rubber and plastic Shore hardness tester is used to determine the hardness of vulcanized rubber and plastic products. The head of the hardness tester is installed on the bench for convenient and accurate measurement. The head of the hardness tester can also be removed and measured at the production site.

Technical Standard

Place the sample on a solid surface, hold the hardness tester, and press the indenter at least 12 mm away from the edge of the sample. When the sample is in full contact, it is read within 1S. The hardness value is measured 5 times at different positions with a distance of at least 6 mm between the measuring points, and the average value is taken (the distance between the measuring points of the microporous material is at least 15 mm). In order to stabilize the measurement conditions and improve the measurement accuracy, it should be The hardness tester is installed on a measuring rack of the same model produced in a supporting production. It meets the requirements of GB/T531 “Test Method for Shore Hardness of Vulcanized Rubber”, GB2411 “Test Method for Shore Hardness of Plastics” and other standards.

Product Parameter

| Index | Parameter |

| Indenter Diameter | 1.25mm±0.15mm |

| Diameter of Indenter Tip | 0.79mm±0.03mm |

| Included Angle of Indenter Taper | 35°±0.25° |

| Needle Stroke | 2.5mm±0.04 |

| Pressure at the End of Needle | 0.55N-8.06N |

| Scale Range | 0-100HA |

| Frame Size | 200mm×115mm×310mm |

| Net Weight of Stand | 12kg |

Product Configuration

One host, certificate, and manual

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top