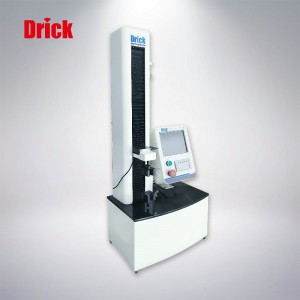

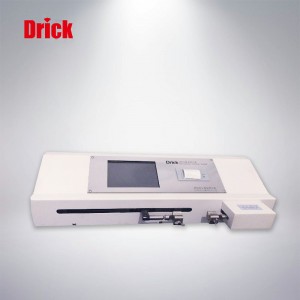

DRK101 Pill Box Opening Force Tester

The DRK101 pill box opening force tester is a new type of high-precision intelligent tester that our company researches and develops according to relevant national standards and adopts modern mechanical design concepts and computer processing technology for careful and reasonable design. It uses advanced components, supporting parts, Single-chip microcomputer, reasonable structure and multi-functional design, equipped with LCD computer Chinese display, with various parameter testing, conversion, adjustment, display, memory, printing and other functions included in the standard

Features

1. The transmission mechanism adopts ball screw, the transmission is stable and accurate; the imported servo motor is adopted, the noise is low, and the control is precise

2. During the test, real-time display of stretching time, load tension, etc.; the latest software has the function of real-time display of tensile curve; the instrument has powerful data display, analysis and management capabilities.

3. Obtain the measurement results directly: After completing a set of tests, it is convenient to directly display the measurement results and print statistical reports, including the average value, standard deviation and coefficient of variation.

4. The professional control software provides a variety of practical functions such as group sample statistical analysis, test curve overlay analysis, and historical data comparison

5. High degree of automation: The instrument design uses advanced domestic and foreign devices, and the computer performs information sensing, data processing and action control, with automatic recovery

Features such as bit, data memory, overload protection, etc.

6. Multi-function and flexible configuration: The instrument is mainly used for plastic film measurement. Changing the configuration of the instrument can be widely applied to the measurement of other materials, such as paper.

Zhang, chemical fiber, metal wire, metal foil, etc.

Applications

At the same time, it can measure paper tension, tensile strength, elongation, breaking length, tensile energy absorption, tensile index, and tensile energy absorption index. It can also achieve 180-degree peeling, 90-degree peeling strength, and constant elongation. , Tests such as constant elongation and length value. Suitable for stretching, peeling, deformation, tearing (trouser-shaped tearing) of plastic films, composite films, flexible packaging materials, adhesives (shear test of specific materials), adhesive tapes, stickers, rubber, paper fibers, etc. Performance tests such as cracking), heat sealing, bonding, piercing force, opening force, low-speed unwinding force, pull-out force (special fixture required) and other performance tests.

Technical Standard

GB/T 12914-1991 “Determination of Tensile Strength of Paper and Paperboard (Constant Speed Stretching Method)” requires design. Also refer to GB 13022-91,

GB/T1040-92, GB2792-81, GB/T 14344-9, GB/T 2191-95, QB/T 2171-95 GB 13022, GB 8808, GB 1040,

GB 4850, GB 7753, GB 7754, GB 453, GB/T 17200, GB/T 16578, GB/T 7122, GB/T 2790, GB/T 2791,

GB/T 2792, ASTM E4, ASTM D828, ASTM D882, ASTM D1938, ASTM D3330, ASTM F88, ASTM F904,

ISO 37, JIS P8113, QB/T 2358, QB/T 1130 and other national and industry standards.

Item Parameters

Specifications 50N 100N 200N (optional)

Accuracy is better than 0.5 level

Deformation resolution 0.001mm

Test speed stepless speed regulation

Number of samples 1 piece

Specimen holding manual

Stroke 400 mm

Dimensions 500mm(L)×300mm(W)×1150mm(H)

Power supply AC 220V 50Hz

Product configuration

Standard configuration: host, computer, special clamp for opening force of medicine box, professional software, communication cable

Optional parts: standard pressure roller, test plate, sampling knife, floating roller fixture, non-standard fixture

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top