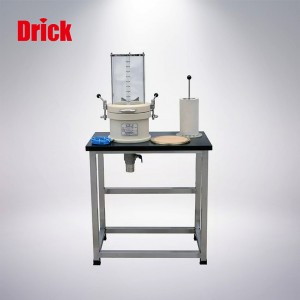

DRK (PFI11) Refiner

Test items: For the determination of the degree of deduction of pulp, etc.

DRK-PFI11 refiner (also known as demolition machine or vertical beater) is used in pulping and papermaking experiments for the determination of the deduction degree of pulp, the determination of pulp sample moisture, the determination of pulp concentration, and the The measurement of dissociation and freeness provides a standard quantitative sample. DRK-PFI refiner complies with ISO5264/2-1979 “Pulp Laboratory Refining-Part 2: PFI Grinding Method” and the experimental standards specified in ISO5264/2 and TAPPIT248.

Instrument principle:

The metered pulp with a specified concentration is placed between the knife roll and the smooth beating cylinder, and the knife roll and the beating cylinder rotate at different circumferential speeds. It acts on the pulp to achieve the purpose of beating.

Features: Adjustable gap between flying knife and slurry tank wall; three sets of standard beating pressure quantitative combination; manual cutter head working up and down, safe operation and convenient cleaning; automatic control of revolution or time, high-brightness digital display rigid head, long time Use, the clearance gap is accurate. Cast base, stable operation and no noise.

Instrument parameters:

1. Pulp tank: inner diameter: medium 250mm 53mm

2. Flying knife rotor: outer diameter: Φ200mm, height 50mm, knife thickness 5mm

3. Flying knife rotor motor: 1.1kW /380v

4. Adjusting distance of deduction gap: 0~25mm.

5. Slurry pool motor: 370W/380v

6. Counter display control range: 0-999999 revolutions

7. Deduction pulp concentration: 5~50%

8. The absolute dry pulp is 5~30g, the standard is 10g.

9. Beating pressure: (3.33±0.1) N/mm blade length; (1.77±0.1) N/mm blade length; (4.89

±0.1)/mm blade length.

11.Overall dimensions: length×width×height 860mm×450mm×1100mm

12. Packing box size: 1000*500*1460mm

13. Net weight: 251Kg; gross weight: 310Kg.

Note: Due to technological progress, the information will be changed without notice. The product is subject to the actual product in the future.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top