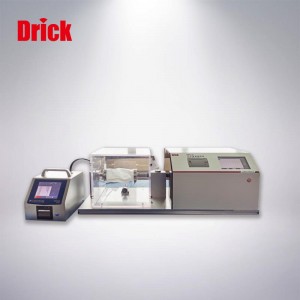

DRK-07C 45° Flame Retardant Tester

DRK-07C (small 45º) flame retardant performance tester is used to measure the burning rate of clothing textiles in the direction of 45º. This instrument is controlled by a microcomputer, and its characteristics are: accuracy, stability, and reliability.

Compliance with standards: design and manufacture of technical parameters specified in GB/T14644 and ASTM D1230 standards.

First. Introduction

DRK-07C (small 45º) flame retardant performance tester is used to measure the burning rate of clothing textiles in the direction of 45º. This instrument is controlled by a microcomputer, and its characteristics are: accuracy, stability, and reliability.

Compliance with standards: design and manufacture of technical parameters specified in GB/T14644 and ASTM D1230 standards.

Second, the main technical indicators of the flame retardant performance tester

1. Timing range: 0.1~999.9s

2. Timing accuracy: ±0.1s

3. Test flame height: 16mm

4. Power supply: AC220V±10% 50Hz

5. Power: 40W

6. Dimensions: 370mm×260mm×510mm

7. Weight: 12Kg

8. Gas pressure: 17.2kPa±1.7kPa

DRK-07C 45°Flame Retardant Tester 800.jpg

Third. Precautions for installation and use of flame retardant performance tester

1. The instrument should be installed in a well-ventilated environment in order to eliminate the smoke and harmful gases generated during the test in time.

2. Check whether the instrument parts are falling off, loose or deformed during transportation, and adjust them.

3. The connection between the air source and the instrument should be firm and reliable, and no air leakage should be allowed to ensure the safety of the test.

4. The instrument must be grounded reliably, and the grounding wire must be installed separately.

5. The temperature is 20℃±15℃, the relative humidity is <85%, and there is no corrosive medium and conductive dust around.

6. The maintenance should be carried out by professional and technical personnel, and should be operated and used strictly in accordance with the instructions.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top